Cash-handling accessories for kiosks and payment terminals

Category description

This category contains accessories that support coin and token handling in kiosks and payment machines: tokens, coin entry bezels and fronts, motorised locks, anti-stringing and coin jam control modules, protective covers for coin validators and multi-way sorters. With products such as the Zseton Eagle – Freedom 25x1.7mm, the metal Alberici 24mm 2+2 token and the Eurocoin brass 26x2.0mm token you can build well-identified, robust token-based systems, while the 12V/24V coin entry with 5-pin anti-stringing sensor and the 3-way Alberici sorter take care of the complete coin path inside the cabinet. Manufacturers like Alberici, WH Münzprüfer, Eagle, Eurocoin, Garlando and Sardi offer industrial-grade parts designed for long lifetime, easy service access and consistent operation in demanding environments.

Cash-handling accessories for industrial kiosks and payment machines

Role in the cash path and typical use cases

Cash-handling accessories are the components that build the physical coin path inside the kiosk, from the entry bezel to the sorter, while providing protection, control and user-friendly operation. In token-based systems it is essential that the token can be identified at a glance and that its geometry and tolerances match the chosen coin validator. Coin entry bezels and fronts shape the user interface of the machine: they determine how easy it is to insert coins, reduce the likelihood of misfeeds and provide protection against liquids, dust and vandalism. Motorised locks and latches allow controlled closing of the entry, so the machine only accepts coins when the system is ready. Anti-stringing and jam-control modules monitor attempts to pull coins back or block the mechanism and trigger targeted actions in the controller.

Product types, manufacturers and highlighted examples

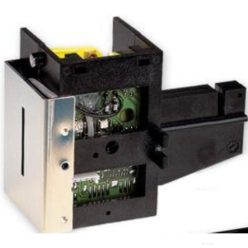

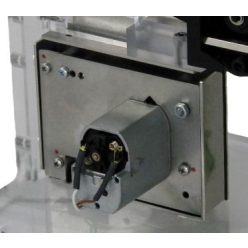

Within this category you will find several product families: tokens, coin entry bezels and fronts, validator covers, motorised locks, sorters and dedicated modules. The Zseton Eagle – Freedom 25x1.7mm, the metal Alberici 24mm 2+2 token, the Eurocoin brass 26x2.0mm token and the Sardi token (Romanian version) offer different diameters and thicknesses to match a wide range of validator configurations. The 12V/24V coin entry with 5-pin anti-stringing sensor, the coin entry with automatic lock in 12V or 24V and the standard locking coin entry from the WH Münzprüfer portfolio provide robust front-end mechanics, selectable supply voltage and straightforward control. The 3-way sorter for Alberici coin validators is used to separate good, reject and collect paths, while the HALO illuminated metal front panel, the MIDI and chrome HALO bezels from Alberici bring high-visibility, backlit design to the coin entry area.

Among the accessories you will also find the E-105 12V intermediate cashbox with motor from WH Münzprüfer, which acts as temporary storage between validator and hopper, and Electronic motor reject 12V DC modules that automatically eject invalid or unwanted coins. Garlando token entry bezels and validator inlets are used in entertainment and sports equipment where dedicated tokens are standard. The manufacturer landscape – Alberici, WH Münzprüfer, Eagle, Eurocoin, Garlando and Sardi – covers the key needs of the cash-handling industry, and the products are tailored to standard cut-outs, connectors and validator interfaces.

Quality, service, operating conditions and financing aspects

Even though these accessories work mostly out of sight inside the machine, they have a major impact on uptime. For long-term industrial use, robust materials, corrosion-resistant surfaces, vandal-resistant mounting and stable electrical connections are essential. Reliable operation also depends on strong local technical support, comprehensive documentation and a structured maintenance plan. During the design phase it is worth clarifying cut-out drawings, cable routing, the coin path and lock control logic, so that installation and service work can be done quickly and predictably.

- availability of local service and support for commissioning, troubleshooting and spare parts supply;

- preventive maintenance plans for cleaning and inspecting bezels, fronts, sorters, locks and protective covers on a regular basis;

- compliance with operating conditions (power supply, ventilation, temperature, humidity, protection against dust and vandalism);

- planned stock levels and scheduled deliveries to meet project milestones and replacement needs;

- flexible shipping options, customs handling and logistics support for domestic and cross-border deployments;

- post-payment terms, invoicing in multiple currencies and bank support for higher-value equipment packages;

- project-specific quotations that cover the complete cash-handling solution, including integration and all accessories.

FAQ – Cash-handling accessories for kiosks

-

Question: Why are dedicated coin entry bezels and fronts important in an industrial kiosk?Answer: With the right geometry and material, coin entry bezels make it easy to insert coins, reduce the risk of misfeeds, protect against liquids and dirt and resist vandalism. As a result, the user experience improves and fewer service interventions are needed.

-

Question: How do industrial anti-stringing and jam-control modules differ from simple, non-industrial designs?Answer: Industrial modules use multi-point sensing, logging and alarms to detect manipulation and blockages, so fraud attempts and jams are identified quickly and the system can respond in a targeted way. This is especially important in high-traffic, 24/7 applications.

-

Question: What should you consider when selecting tokens for a new installation?Answer: Key aspects include diameter and thickness tolerances, edge geometry, material choice, magnetic properties and marking. Together these ensure that the token works reliably with the validator and is clearly distinguishable from circulating coins.

-

Question: How do these accessories help optimise the total cost of cash handling?Answer: Well-chosen accessories reduce the number of jams and failures, shorten service time and improve the user experience. This leads to less downtime, more predictable operation and longer overall lifetime of the installation.